Project Management consultancy

Scope of Project Management Consultancy:

Project Management services include:

Stakeholder Liaison

The PMC roles envisages into the following key areas: Project Management and Control:Scope: To manage and integrate the activities of the Engineering, Procurement and Construction Phases of the project.

Deliverable: Project Coordination Manual

Project Coordination Manual will define:

Monitoring / Control Aspects:

Process:

Execution:

Project Governance Structure

Design:

Activities:

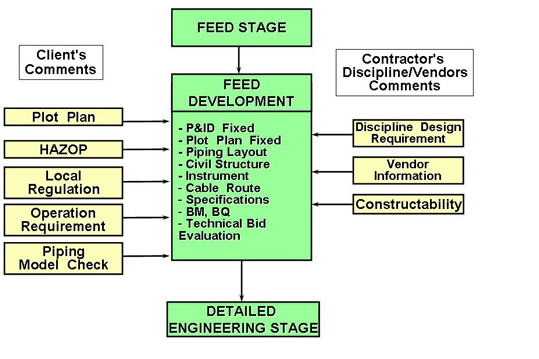

Example of FEED stage process flow:

Key Stages:

The process of engineering work to produce the required deliverables for process, mechanical, piping engineering, functional aspects, specifications depicting every detail of a facility, Engineering involves varieties of specialties, which include :

Procurement Assistance & Vendor Inspection

Scope:

Stages:

Site Inspection

Process and Safety Audit

Get In Touch With Us

We seek to create long-term relationships built on results.